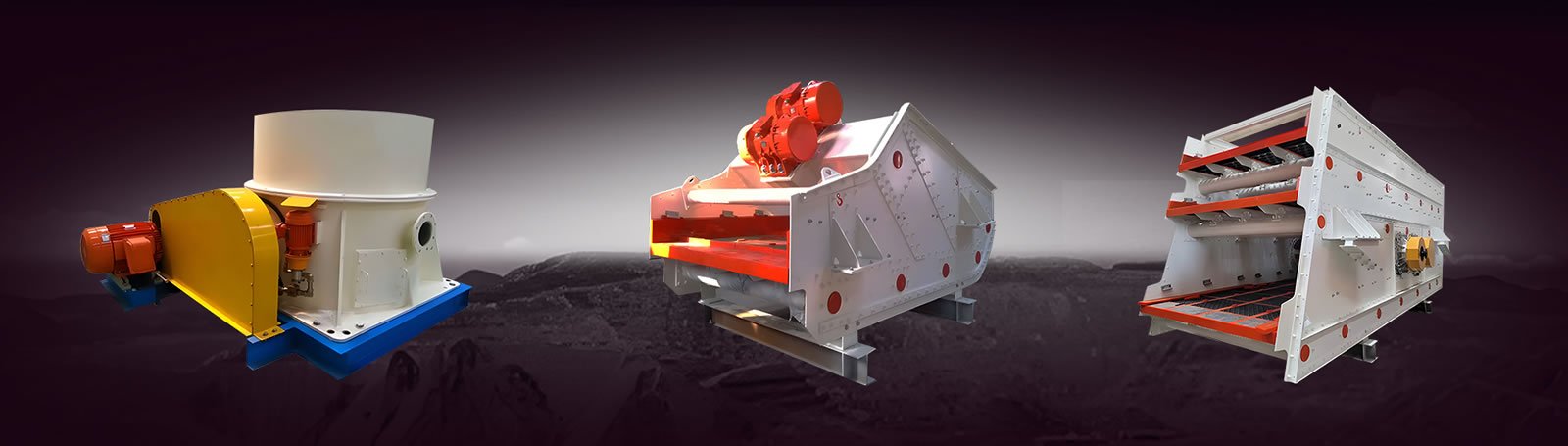

Products Description

Sieve Bend Screen is suitable for dehydration and demediation of foamy coal and coal slime in coal mines. It can also be used for dehydration of non-coal fine sand. The feed size is less than 5mm

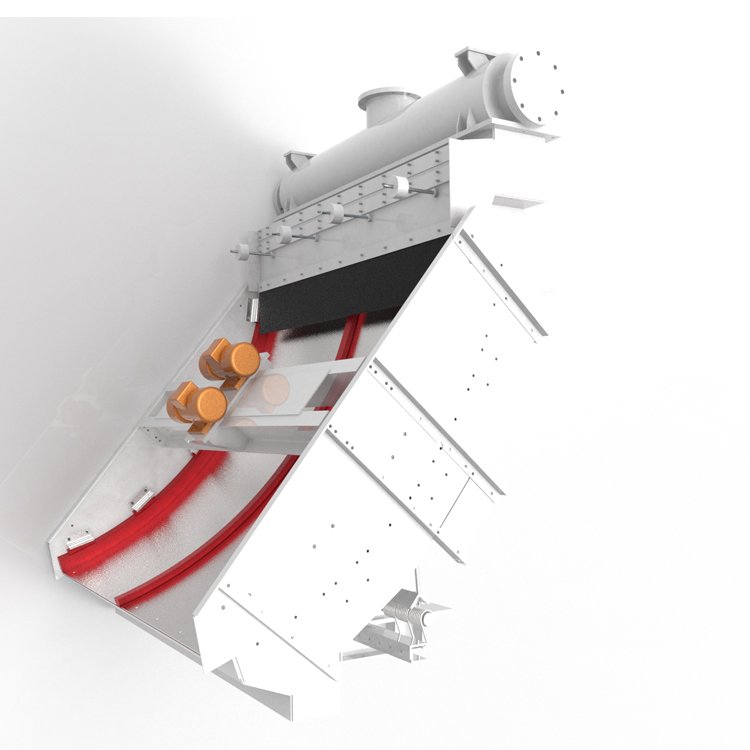

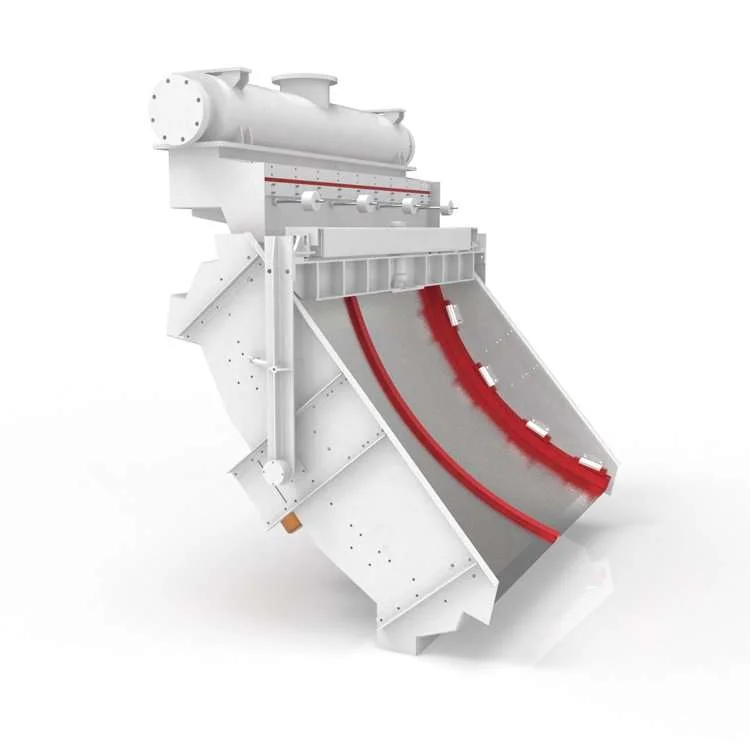

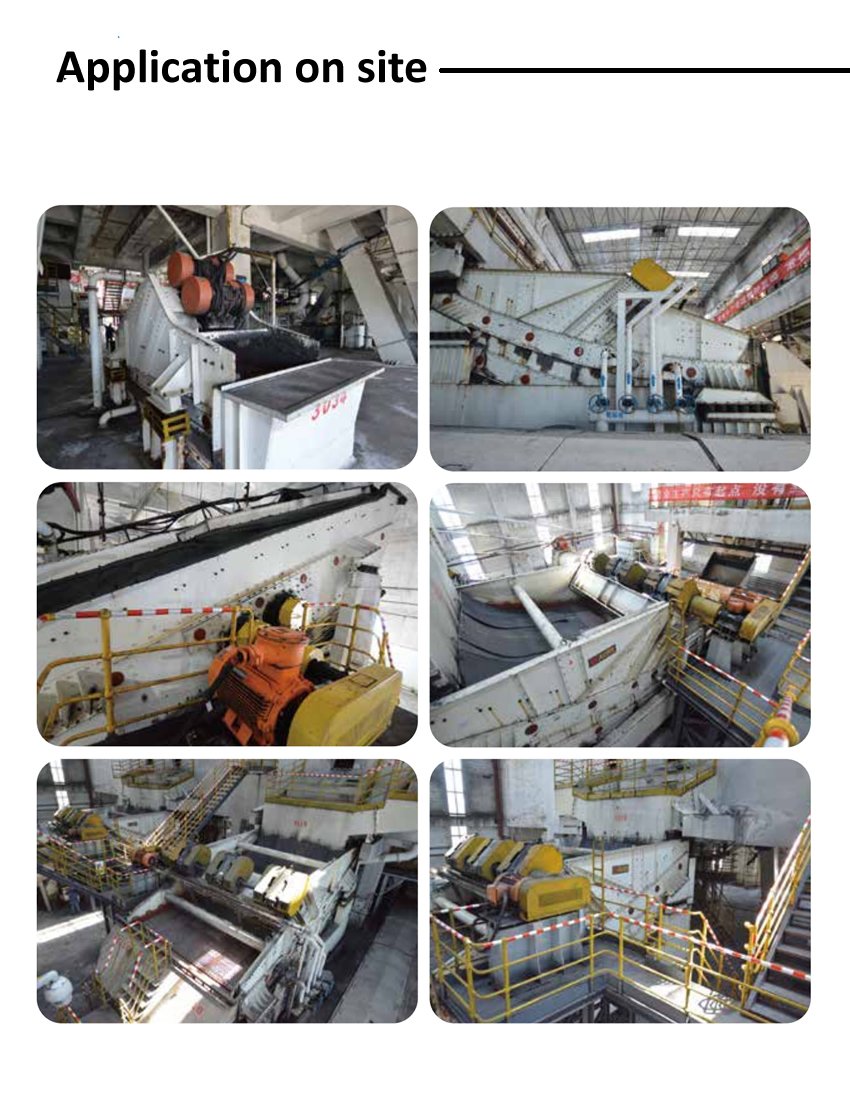

Working process of vibrating arc screen: add a vibration motor to the flip arc screen. The function of the vibration motor during operation is to clean up the piled material on the screen surface in time. At the same time, the water film generated by the slurry and the screen surface is destroyed by vibration in time, and the screening efficiency is improved by increasing the opening rate.

Performance characteristics:

1. The screen box adopts a pivot steering structure and can rotate 180°. It can be used in reverse regularly during use, which can not only extend the service life of the stainless steel screen plate, but also improve the effect of dehydration, desludging and demediation.

2. The vibrating arc screen has two wrap angles of 45° and 60°, and the curvature radius has two series of 1016mm and 2032mm.

3. The screen surface width is available in several specifications: 900mm, 1200mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2200mm, 2400mm, 2800mm, 3000mm, 3200mm, 3400mm, 3600mm, 3900mm.

4. Users can choose the wrap angle, arc radius and width of the curved screen according to their needs.

Technical Parameters

| Model | Model of screen deck | Capacity(t/h)

aperture 0.5mm |

Wrap Angle | Radius of curvature | Power(kw) | Feed size (mm) | Weight(t) | Overall dimension(mm) |

| AVR0945 | 900×2150mm | 90 | 45 | 2032 | 0.37 | 0-5mm | 1.5 | 1660*1000*2385 |

| AVR3960 | 3900×2320mm | 550 | 60 | 2032 | 0.45 | 0-5mm | 4.7 | 2308*4016*2994 |

| AGVR0945 | 900×2150mm | 90 | 45 | 2032 | 0.37 | 0-5mm | 1.5 | 2155*1266*2642 |

| AGVR3960 | 3900×2320mm | 550 | 60 | 2032 | 0.45 | 0-5mm | 4.3 | 2300*4460*2680 |

Tags:

Technical parameter

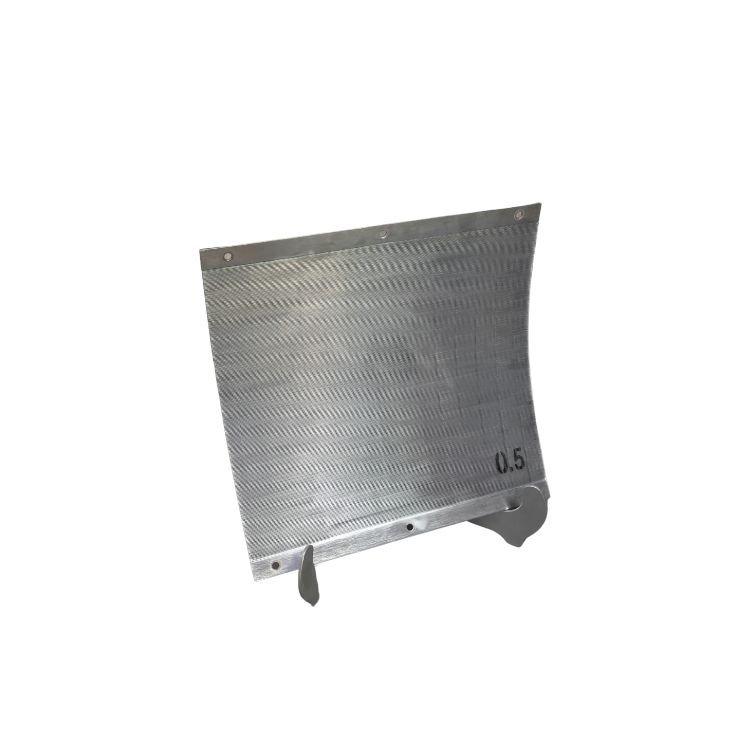

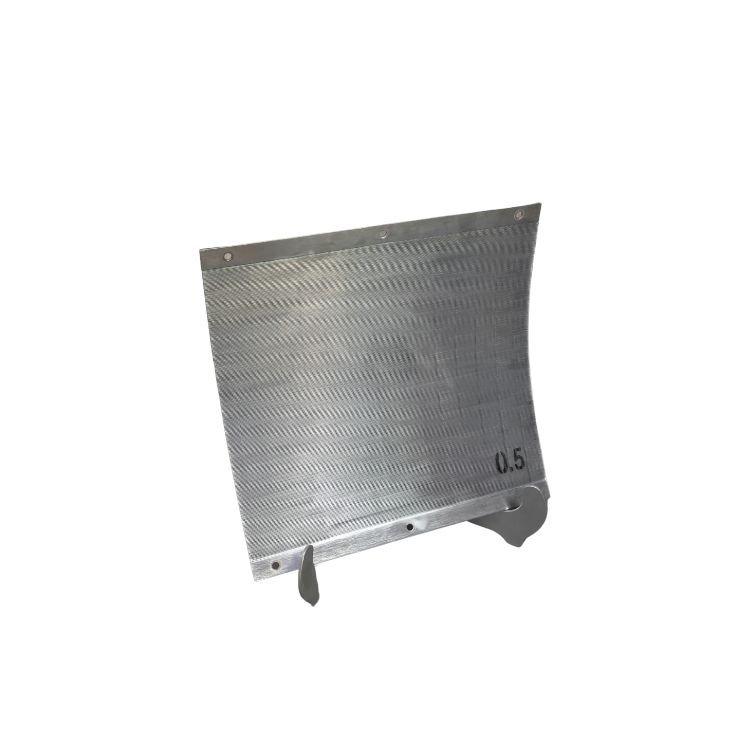

Bend Sieve

Bend Sieve

Bend Sieve

High Open area :The open area is more than 1.6-2.5 times higher than that of traditional sieve bend panel

High wear resistance : In addition to material roling (or sliding) wear, there is also leakage wear. As far as the sieve bend panel isconcerned, the leakage wear is greater than the surface wear, and the eficient sieve bend panel just makes up for the performance that thetraditional sieve bend panel does not have, which not only increases the screening rate, but also extends the service life.

Low energy consumption : The open area is increased, the vibration screen can completely stop the vibration motor, and the dehydrationefect can also be achieved, the weight of the screen is reduced,the motor load rate is reduced, and the power consumption is reduced.

Light weight : Easy to change, more convenient operation of staff, further improve personal safety.

The cost can be saved when the equipment is selected : High open area screen is selected, and vibration screen can be no longerconsidered when the equioment is selected