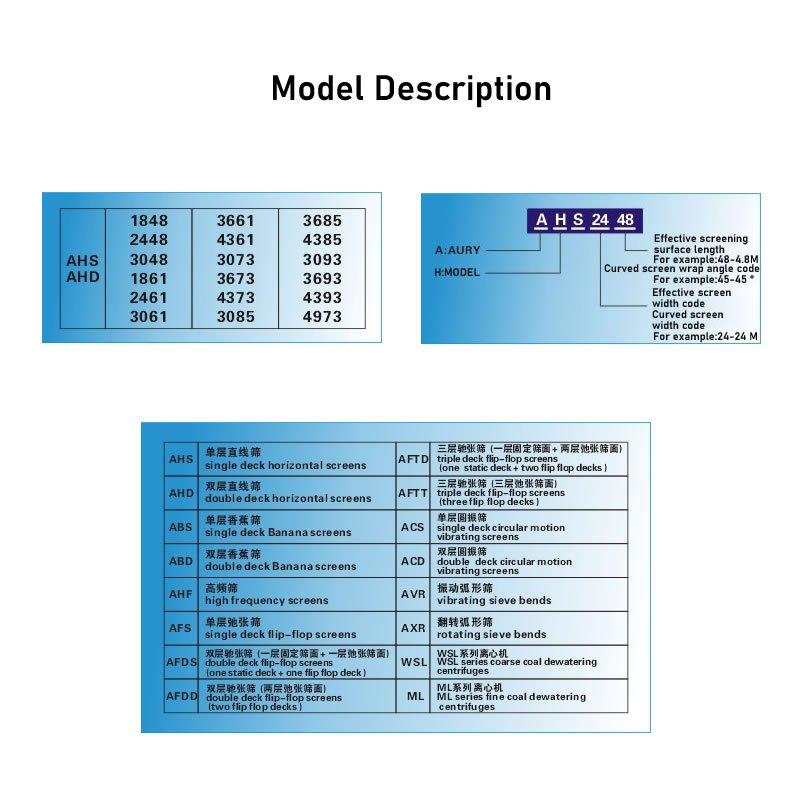

Products Description

Quarry vibrating screens are specifically designed to provide high-performance separation and classification of materials in the demanding quarrying industry. Built to withstand tough environments, these screens efficiently sort aggregates, gravel, and other materials, ensuring optimal product quality and consistency.

TSX SCREEN has the following technical characteristics and advantages:

● Simple and compact structure, high rigidity, high strength, balanced force distribution, and large safety factor;

● Reasonable setting of vibration parameters to avoid the natural frequencies of each level of the screen body and reduce the influence of resonance;

● Long service life, the service life of the screen body is up to 10 years, and the service life of the exciter is more than 60,000 hours;

● Light weight, low power consumption, high vibration intensity (9-12mm), high screening efficiency (>95%);

● Select domestic brand patented screen surface configuration, high screening efficiency, large material processing capacity;

● Low working noise, noise level is less than 75 decibels, and stable operation;

● The whole machine working system is S1, ensuring 24-hour stable and continuous operation;

● Imported FFT professional frequency analyzer is used for frequency response and dynamic analysis;

● Complete variety, which can fully meet the screening process requirements of different material characteristics and processing volume;

● The screen machine is easy to operate and maintain, safe to use, cost-effective, with sufficient spare parts and timely and thoughtful service.

Working principle of vibrating screen:

● The motor rotates when powered on, and the belt drive mechanism adjusts the speed;

● The driving force is transmitted to the main drive shaft through the secondary shaft;

● The exciter is driven to operate to generate linear vibration force, and the direction of the exciting force is 45° with the horizontal angle;

● The linear vibration force acts on the screen body in a reciprocating manner, causing the screen body to vibrate on the buffer spring, and at the same time, the buffer spring reduces the dynamic load of the screen body on the supporting foundation of the screen machine;

● The screen body drives the screen surface to vibrate synchronously, and transmits force to the material on the screen. The impact material is thrown up on the screen surface and layered and screened according to the specified particle size;

● The material is continuously buffered from the feed chute to the receiving plate, and is screened through the screen surface. The underscreen material is discharged into the underscreen chute, and the overscreen material is discharged into the discharge chute;

Tags:

Technical parameter

Screen Vibrator

Screen Vibrator

Screen Vibrator

Quarry Vibrating Screen drive system uses SKF bearings and seals, which have strong driving force, solid structure, reliable operation and long service life.