Products Description

The machine is self-driven by diesel engine. It can reach any position of the work site under any terrain conditions. The transfer is convenient and fast, which can greatly reduce the pre-processing operation of materials and facilitate the adjustment of all auxiliary mechanical equipment. Through wireless control, it is very easy to drive the screening machine onto the trailer and transport it to the work site over a long distance. Because there is no assembly time, the equipment can be put into operation immediately after arriving at the work site. No electricity is required, and the diesel engine provides strong power. Its optimized design can meet the most required technical characteristics of the screener, with high productivity and uniform particle size of the finished product.

Main advantages:

Competitive area ensures high processing capacity.

The equipment integrates multiple hydraulic conveyor belts, showing high stacking capacity.

The control panel interface with numbers and colors is easy to identify, and it is equipped with a start/stop function for easy operation.

*Optimized fuel consumption reduces your production and operation costs.

Multiple specifications of modular screens are available to suit different material and process requirements.

CMS equipment status monitoring system is standard.

| AS500H crawler mobile screening equipment parameters | |||

| model | AS200H | AS350H | AS500H |

| Processing capacity | 200tons/hour | 350tons/hour | 500tons/hour |

| Material looseness | 0.9-2t/m³ | 0.9-2t/m³ | 0.9-2t/m³ |

| Maximum particle size | 300mm | 300mm | 500mm |

| Repose Angle | 30-50° | 30-50° | 30-50° |

| Processing output materials | 3 products | 3 products | 3 products |

| Maximum volume of lubrication tank | 6m³ | 7.5m³ | 9m³ |

| Feeding height | 3.5m | 3.6m | 3.7m |

| Turn far (L x W x H) | 10.7×2.55×3.1m | 13.8×2.9×3.7m | 17.4×3.25×3.7m |

| Working (L x W x H) | 11.9×17.5×5.5m | 16.5x18x6m | 19×18.5×6.5m |

| Total weight of equipment | 28t | 32t | 35t |

| Screening machine (standard) | Circular Vibrating Screen | Circular Vibrating Screen | Circular Vibrating Screen |

| Vibration surface | 1200×3800 | 1500×4200 | 1800×4200 |

| Relaxation screen (optional) | Double layer relaxation screen | Double layer relaxation screen | Double layer relaxation screen |

| Vibration surface | 1000×3800 | 1200×4200 | 1500×4200 |

| Plate chain feeder | 300tons/hour | 450tons/hour | 600tons/hour |

| Feeder width | 800mmx3575mm | 1000mmx3575mm | 1200x3575mm |

| drive | Cummins diesel National IV engine + hydraulic system |

Cummins diesel National IV engine + hydraulic system |

Cummins diesel National IV engine + hydraulic system |

| Engine power | 92kw | 92kw | 110kw |

| Relocation | Remote control Strickland Crawler-style walking |

Remote control Strickland Crawler-style walking |

Remote control Strickland Crawler-style walking |

| Intelligent monitoring | (1) Real-time status monitoring (2) Abnormal alarm (3) Vibration data analysis (4) Fault prediction and diagnosis (5) System management (6) Mobile APP |

(1) Real-time status monitoring (2) Abnormal alarm (3) Vibration data analysis (4) Fault prediction and diagnosis (5) System management (6) Mobile APP |

(1) Real-time status monitoring (2) Abnormal alarm (3) Vibration data analysis (4) Fault prediction and diagnosis (5) System management (6) Mobile APP |

Tags:

Technical parameter

Heavy Duty Plate Chain Feeder

Heavy Mobile Screen

Vibration Exciter

Heavy Duty Plate Chain Feeder:

Excellent performance of each component, one-piece chain track plate, stable and continuous operation, easy maintenance, with lining, can operate continuously for a long time for various materials, can adjust the product processing volume through adjustment, hydraulic transmission, overflow protection, no need to worry about material jamming, thorough inspection and acceptance before leaving the factory.

Heavy Mobile Screen:

Hooker high-strength bolt-on mechanism, economical and efficient, stable operation, maintenance-free universal shaft, frequency adjustment to optimize equipment production efficiency, thickened surface support longitudinal beam, pre-factory testing and acceptance, unique vibration reduction technology, improve product handling capacity through equipment specifications rather than increasing the number of equipment, modular screen plate solution, easy installation, low cost of use.

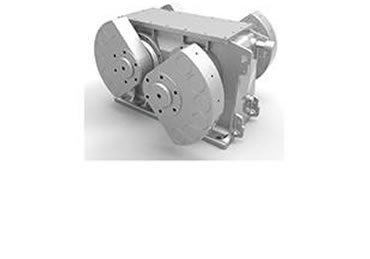

Vibration Exciter:

Vibration Exciter is used to generate controlled vibrations in various industrial applications, primarily for driving vibrating screens, feeders, and other equipment. Its main purpose is to create consistent and adjustable vibration patterns that facilitate the effective separation, classification, and movement of materials.