Products Description

Less moving parts in the TSX ML series centrifuge design means efficient, reliable operation, and lower downtime and maintenance costs.High rotate speed, slime recovery, and drainage efficiency.All moving parts are enclosed in a protective cover, easy to operate reliably.

Working principle:

ML series centrifuge is a universal horizontal scraper unloading centrifuge. The material reaches the scraper and the bottom of the screen basket through the feed pipe, and is pressed against the screen surface by the centrifuge. Due to the speed difference between the scraper and the screen basket, the material layer moves evenly to the large end of the screen basket under the action of the scraper. The dehydrated material is thrown out from the large end of the screen basket and falls into the discharge port at the bottom of the casing. Under the action of centrifugal force, the water in the material passes through the material layer and the screen gap and is thrown around the casing, and flows along the inner wall to the discharge port.

Features:

Horizontal vibrating centrifuge is not only suitable for coal, it can also be used for dehydration and separation of fine tailings, medium ore, coarse mud, fine gravel, sand and potassium fertilizer dissolved residues.It is specially designed for dehydrating small particles of 0.15-3mm coal slime.

centrifuge adopts the domestic leading level of screen basket, which has the advantages of large opening rate, screen seam is not easy to block, high dehydration efficiency, high strength, not easy to deform, wear resistance, long service life, convenient disassembly and assembly, large workload, low power consumption, etc.

Rotating part:

Imported SKF special bearings are adopted, with large load capacity and low noise. The inclination angle and end face of the screen basket are optimized for easy discharging and disassembly.

The rotating connection surface adopts a professional double sealing system design with good sealing effect and long service life.

Vibration part:

Two vertically installed vibration motors are used as the excitation source, with stable vibration and stable amplitude. It has the characteristics of simple structure, convenient adjustment, short maintenance time, less maintenance, no oil leakage, reasonable layout and reliable performance.

Machine body:

Box-type structure design, all easily worn parts are inlaid with imported high-strength wear-resistant tiles, and CNC machine tools are used to precisely process each assembly surface to fully ensure the installation accuracy and coaxiality of the equipment. All welding parts meet the first-level flaw detection inspection standard and are annealed to eliminate stress. The overall structure has high strength, good stability, compact structure and high safety factor.

Lubrication system:

Adopts a concentrated pressure circulation lubrication system with thin oil. The system has multiple functions such as lubrication, cooling, and oil purification, with fewer lubrication points, low noise, and low maintenance. You only need to refuel and change the oil regularly. The labyrinth lubrication uses an imported automatic oiler, which is automatic and maintenance-free.

Tags:

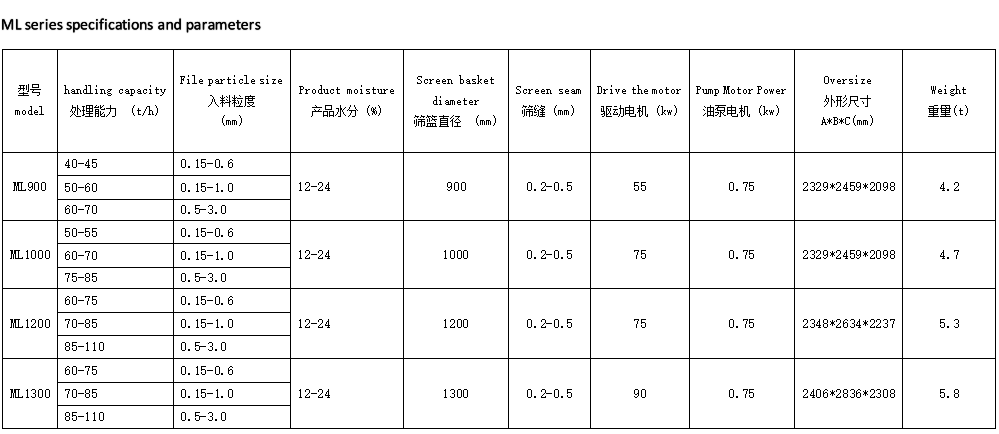

Technical parameter

ML Horizontal Vibrating Centrifuge

ML Horizontal Vibrating Centrifuge

ML Horizontal Vibrating Centrifuge

Vibrating Section:The ML centrifuge incorporates a professional torque overload protection device, and an oil supply system protection device.

Machine Section:The ML Centrifuge housing, scraper, and feed chute are all covered with high-density Alumina wear tiles to reduce wear and extend the machine service life.

Lubrication System:An independent lubrication system is used for lubrication, cooling, and cleansing. The system is equipped with an oil circuit protection function to ensure the operation safety of the system with less maintenance.