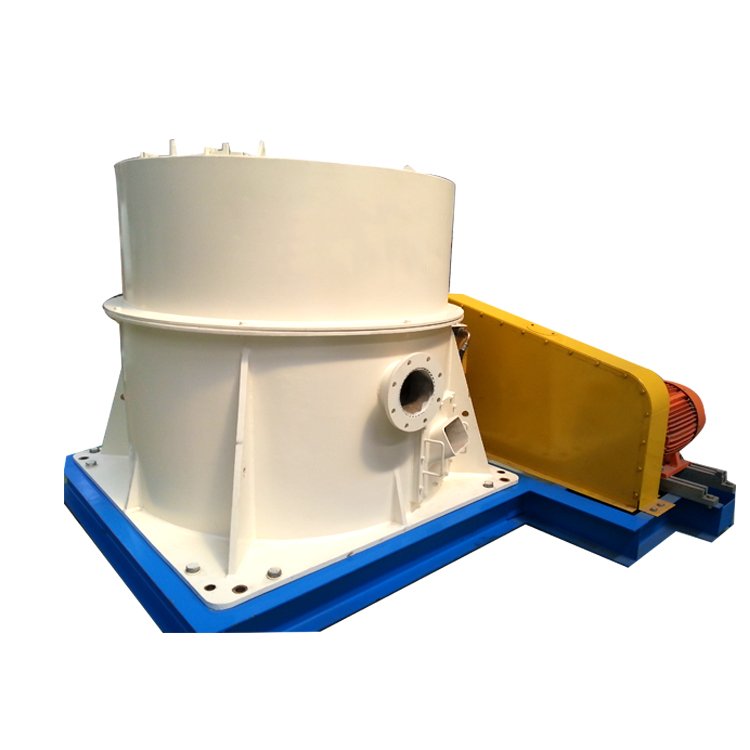

Products Description

Features: The vertical scraper unloading centrifuge is suitable for the separation of solid-liquid two-phase suspensions containing solid particles with a particle size greater than 10μm. Generally speaking, it is more appropriate to use this machine when the weight concentration of solid phase particles in the suspension is greater than 25%. Therefore, vertical scraper centrifuges have been widely used in coal, chemical, light industry and other industries. centrifuge adopts the domestic leading level screen basket, which has the advantages of large opening rate, screen seam is not easy to block, high dehydration efficiency, high strength, not easy to deform, wear resistance, long service life, convenient disassembly and assembly, large workload, high consumption The advantages of small electricity and so on.

Rotation part:

Structure optimization design, high-precision, high-strength differential structure, imported SKF special bearings, long service life, low noise;

The scraper adopts a new structure, with stable rotation and uniform distribution, which effectively reduces the load fluctuation when handling a large amount of material;

the whole machine has few transmission parts, reliable operation, low maintenance and low maintenance cost. The rotating speed of the screen is high, the recovery rate of coal slime is high, and the dehydration effect of the product is good.

All rotating parts are enclosed inside the protective cover, which is easy to operate, safe and reliable.

Vibration part:

Professional configuration of oil supply system abnormal protection device

Body part:

All wear-resistant parts such as centrifuge shell and scraper are inlaid with imported high-strength wear-resistant tiles.Professional design of feeding port and discharge port to ensure smooth passage of materials, strong adaptability to material changes, and prolong service life.

Lubrication system:

Professionally equipped with independent lubrication and cooling system, which has many functions such as lubrication, cooling and oil purification, and is equipped with oil circuit protection function to ensure the safety and reliability of the lubrication system with less maintenance.

Working principle of vertical scraper centrifuge: After the coal-water mixture with a certain concentration enters the centrifuge, it enters the gap between the screen basket and the scraper through the distribution plate. Under the action of centrifugal force, the water passes through the material layer and splashes through the screen. To the lining plate of the upper cover, flow into the sump of the base along the lining plate, and drain out of the body through the filtrate pipe. The solid phase material accumulated on the inner side of the sieve basket is scraped down along the sieve basket to the bottom of the sieve basket by the scraper using the speed difference between the sieve basket and the scraper, and is discharged through the bell hood and the outlet cone.

Tags:

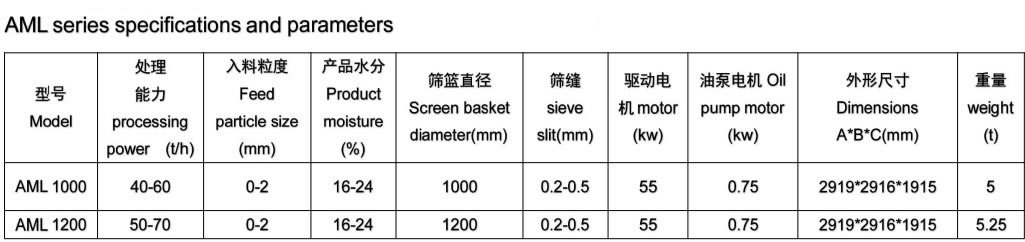

Technical parameter

Mesh Vibrating Screen With Double Meshs

Mesh Vibrating Screen Sperating

Mesh Vibrating Screen Sand Single

Optimized AML Series Vertical Scraper Centrifuges feature a high-precision differential mechanism, SKF bearings, and low noise operation. The new scraper design ensures smooth function, even basket loading, and reduced vibration. Fewer moving parts in the AML series enhance efficiency, reliability, and lower maintenance costs. High rotation speed improves slime recovery and drainage efficiency. All moving parts are enclosed for safe, easy operation.