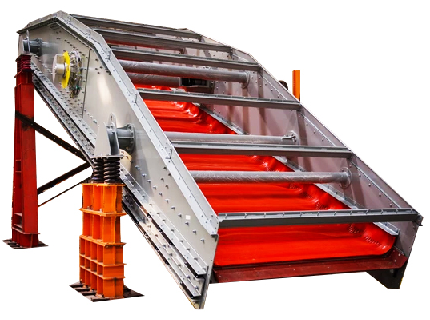

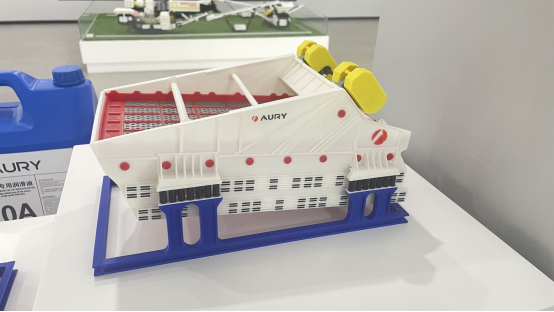

In the field of mineral processing, the flip-flop screen has become an ideal equipment for processing viscous and difficult-to-screen materials due to its unique design and high efficiency. This article will analyze the core advantages of the flip-flop screen from the aspects of structural characteristics, working principle, scope of application and technical parameters.

Top protective cover: double guarantee of safety and environmental protection

The Flip-Flop screen generates extremely high vibration intensity (up to 50g, far exceeding the 5g of ordinary vibrating screens) when working due to the principle of double vibration. Although this strong vibration greatly improves the screening efficiency, it may also cause material splashing. For this reason, a bulletproof cloth sealed protective cover is used on the top of the equipment, which not only effectively prevents material ejection and ensures operational safety, but also significantly suppresses dust diffusion and meets environmental protection requirements. This design takes into account both production safety and green mine construction needs, and has become an important highlight of the flip-flop screen.

Working principle of flip-flop screen: elastic vibration drives efficient screening

The flip-flop screen achieves dynamic screening through the alternating movement of the floating screen frame and the fixed screen frame:

Dual vibration system:

The floating screen frame is connected to the fixed frame through shear springs or rubber shock absorbers, and the motor drives the eccentric shaft to generate exciting force, driving the floating frame to make high-frequency reciprocating motion.

Relaxation effect:

The screen surface forms periodic tension and relaxation under the action of elastic elements, generating a vibration intensity of up to 50g, strongly destroying the material adhesion layer and accelerating the screening of fine particles.

Self-cleaning function:

The continuous deformation of the screen effectively prevents blockage, especially suitable for wet and sticky materials.

Scope of application: Accurately match complex screening requirements

The flip-flop screen is designed for dry deep screening of fine-grained viscous materials below 13mm. Typical application scenarios include:

The flip-flop screen is designed for dry deep screening of fine-grained viscous materials below 13mm. Typical application scenarios include:

Feed range:

The standard configuration handles 0-50mm materials; after adding a fixed screen surface, the maximum feed particle size can reach 300mm, which is suitable for primary screening after coarse crushing.

Applicable materials:

Wet coal, clay minerals, coke and other highly viscous and easy-to-block materials that are difficult to handle with traditional screens.

Industry fields:

Coal washing, metallurgy and mining, building materials and environmental protection solid waste treatment, etc.

Technical characteristics and parameter control

Advantages of amplitude and vibration intensity:

The amplitude of the Flip-Flop screen is higher than that of ordinary vibrating screens. Combined with its floating frame amplitude (12-20mm), it generates a vibration intensity of 50g (ordinary screens are only 5g) through the principle of double vibration, which significantly improves the looseness and screening efficiency of materials.

High vibration intensity can strongly overcome the adhesion of materials, especially suitable for materials with high moisture content and easy to agglomerate, and the screening efficiency is improved by more than 30%.

Flexible control:

By increasing or decreasing the number of shear springs or adjusting the stiffness of the rubber shock absorber, the amplitude of the floating frame can be accurately controlled to adapt to different working conditions. For example, sticky materials require a larger amplitude to enhance the loosening effect, while fragile materials can reduce the amplitude to reduce the risk of crushing.

The mining flip-flop screen has overcome the difficulty of screening sticky and wet materials with its higher amplitude and super vibration intensity (50g) than ordinary screens, and has achieved multiple breakthroughs in safety protection, screening efficiency and environmental protection performance. Its innovative design not only meets the needs of efficient production in modern mining, but also promotes the continuous upgrading of the industry towards intelligence and greenness.