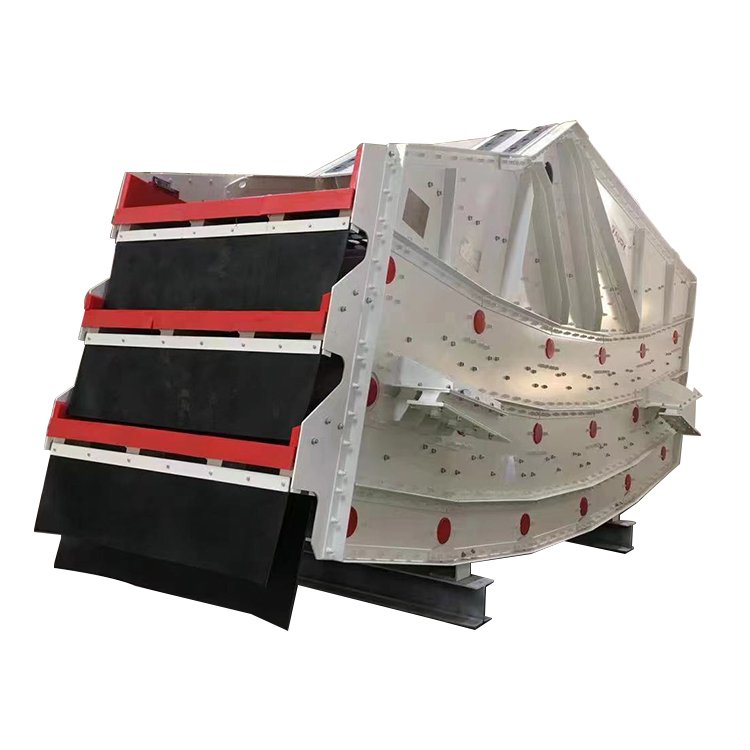

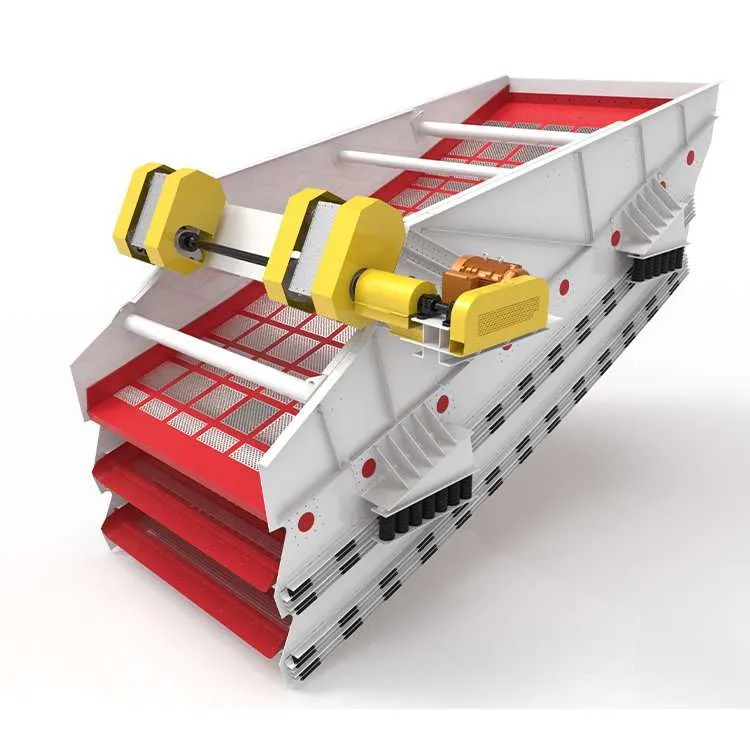

TSX SCREEN Vibratory Classifier Screen utilizes advanced vibratory technology to effectively grade and classify a wide range of materials, including sand, coal and aggregate. Built with durability and reliability in mind, it features customizable screen configurations and adjustable vibratory settings to meet your specific processing needs.

TSX SCREEN Vibratory Screener Machine utilizes advanced vibratory technology to effectively grade and classify a wide range of materials, including sand, coal and aggregate. Built with durability and reliability in mind, it features customizable screen configurations and adjustable vibratory settings to meet your specific processing needs.

Engineered for durability and efficiency, the TSX SCREEN Shaker Deck Screen uses a powerful vibrating motion to effectively sort and grade materials, increasing your processing capabilities. Ideally suited for mining, material dewatering and aggregate processing applications, the TSX SCREEN Shaker Deck Screen can handle a wide range of materials from sand to ore.

Applicable materials:River pebbles, granite, basalt, iron ore, quartz stone, diabase, iron ore, gold ore, copper ore, etc.

Hydraulic cone crushers are ruggedly constructed and feature adjustable settings to handle a wide range of materials, including ores and aggregates, making them ideal for handling a variety of materials to suit different operational needs. Able to handle tough materials and reduce downtime, hydraulic cone crushers are essential to increasing productivity and efficiency in mining operations.

The screen vibrator plays a vital role in the screening industry by enhancing material movement and separation efficiency, leading to improved processing and productivity.

Vibrating Rock Screen plays a vital role in the rock industry. It can effectively classify and dehydrate materials, grade materials of different sizes, optimize the processing process and increase productivity.

CS High Efficiency Cone Crusher has the characteristics of large crushing force, high efficiency, high processing capacity, low operating cost and convenient adjustment. The structural design is reasonable, the crushed product particle size is uniform, and the circulating load is reduced. Each model of this series of cone crushers produced by our company has a variety of cavity types. Users can choose the most suitable cavity type according to the type of material, finished product particle size, and particle size distribution requirements to achieve the best production effect.