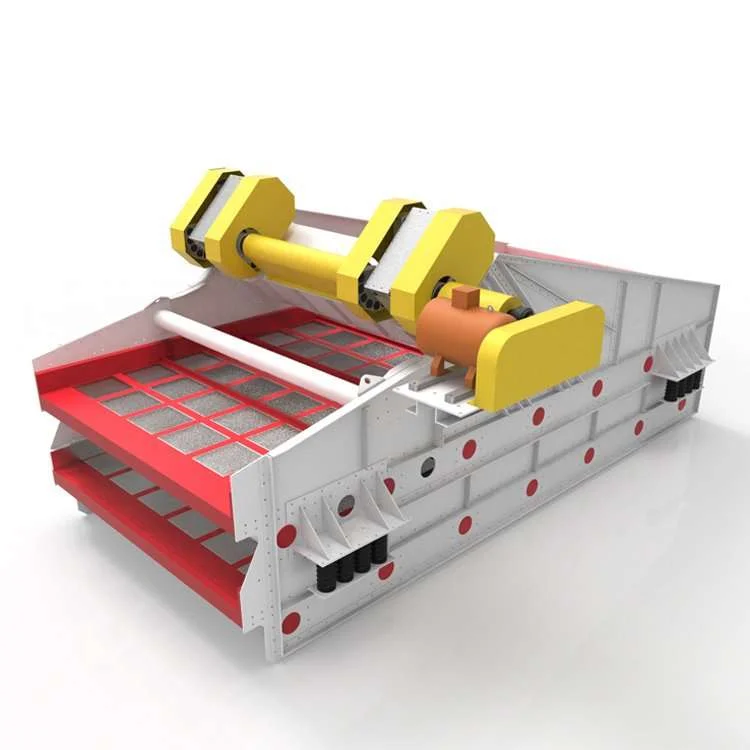

TSX SCREEN Sand Vibrating Screen uses advanced vibration technology to minimize clogging and maximize production, and is available in customizable sizes and configurations to meet the needs of different scenarios.

TSX SCREEN Screen Equipment utilizes advanced vibratory technology to effectively grade and classify a wide range of materials, including sand, coal and aggregate. Built with durability and reliability in mind, it features customizable screen configurations and adjustable vibratory settings to meet your specific processing needs.

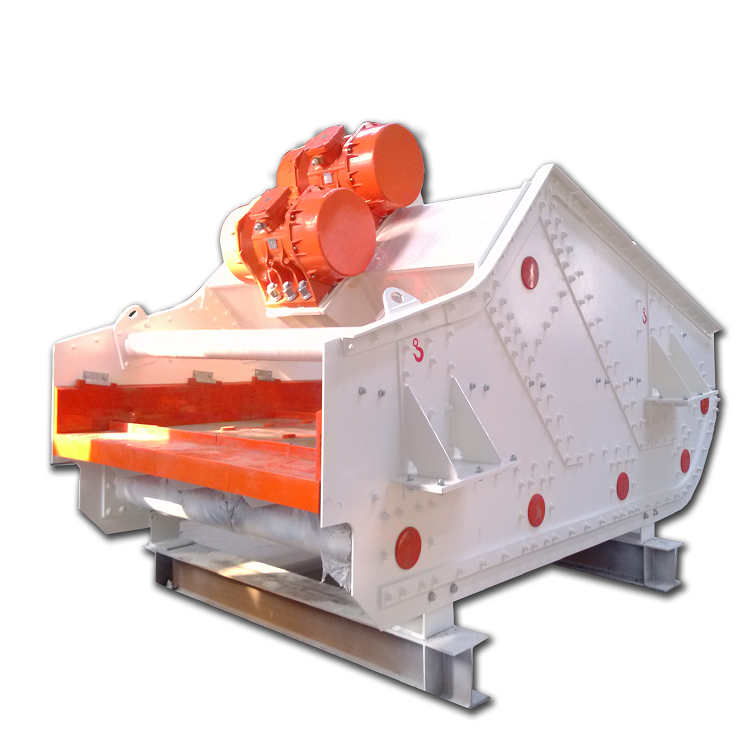

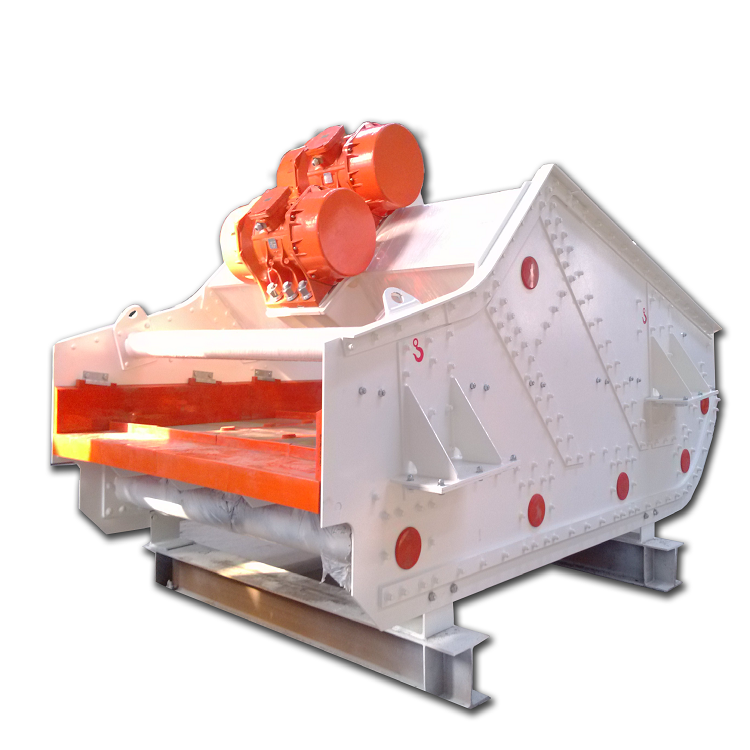

Linear Vibrating Screen are traditional vibrating equipment used to screen dry and wet materials.

Shaker Screen can be designed with different aperture sizes for materials of different particle sizes. It adopts the internationally leading screen plate with high opening rate, the screen seam is not easy to be blocked, the de-mediation and dehydration effect is good, and the service life is long.

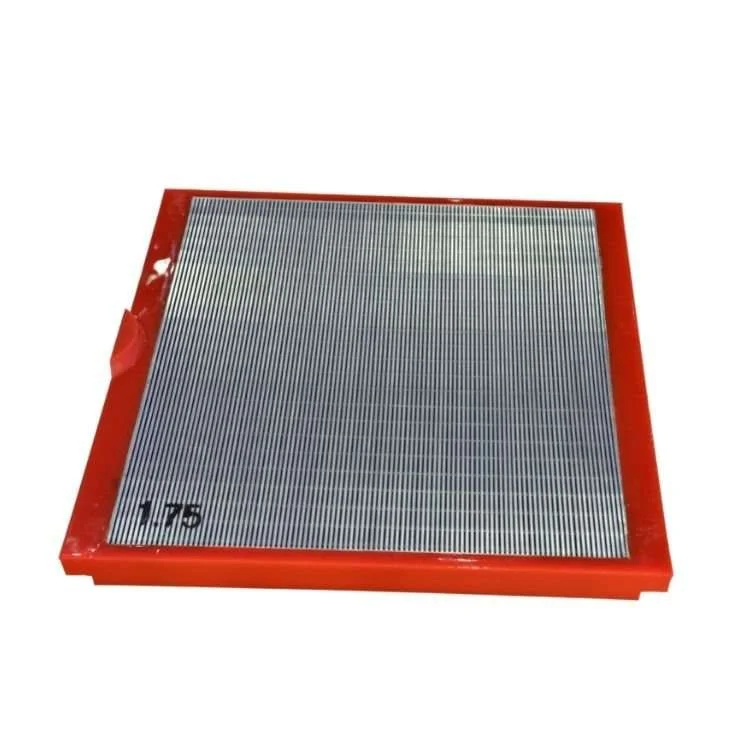

Screen Mesh can be designed with different aperture sizes for materials of different particle sizes. It adopts the internationally leading screen plate with high opening rate, the screen seam is not easy to be blocked, the de-mediation and dehydration effect is good, and the service life is long.

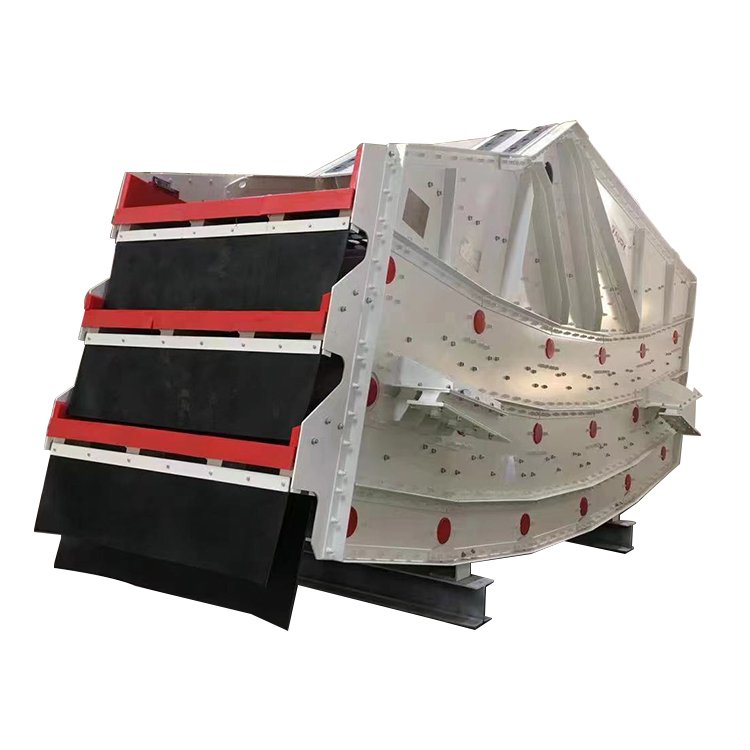

Heavy Duty Sieve is built to withstand the harshest conditions in demanding industrial environments. Designed for maximum durability and performance, it efficiently handles large volumes of material while providing precise material separation, dewatering and classification.

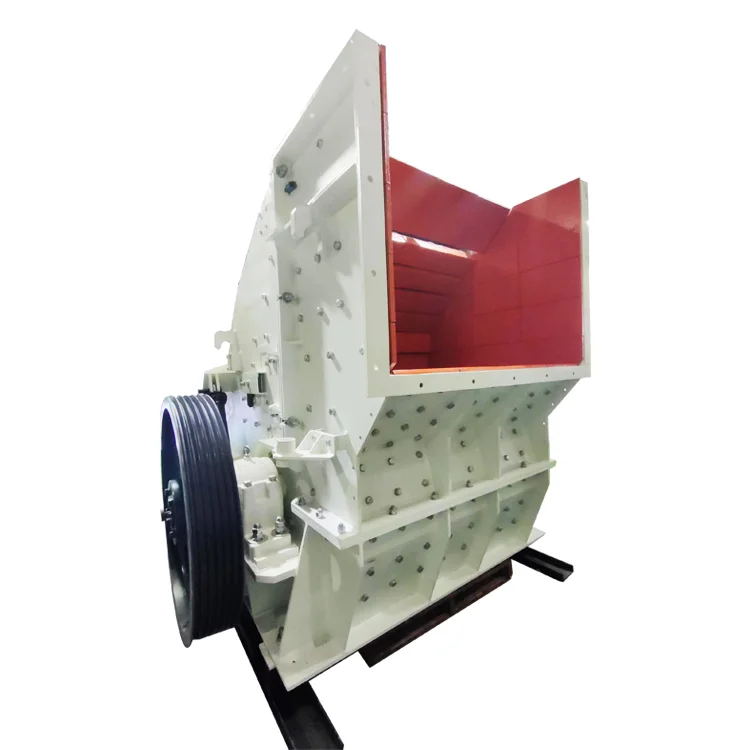

Impact Crushing Screen is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the plate hammer action area, it is crushed by impact with the plate hammer on the rotor, and then is thrown to the impact device for crushing again, and then bounces off the impact lining. Return to the plate hammer action area for re-crushing. This process is repeated.

Filter screen mesh is specifically designed to provide excellent filtration performance for a variety of industrial applications. This high-quality mesh is carefully designed to effectively separate solids and liquids.

Vibrating Screen Machines separate and sort a wide range of materials across a wide range of industries. Vibrating Screen Machines utilize advanced vibration technology to effectively sort and filter materials, ensuring optimal product quality and consistency.

Vibrating Dewatering Screen are specifically designed to enhance the separation of solids from liquids, ensuring optimal moisture removal in various industrial applications.

Aggregate vibrating screens are engineered to provide efficient separation and classification of various aggregates in the construction and mining industries. Designed for durability and high performance, these screens effectively handle large volumes of materials, ensuring precise sizing and optimal product quality.

TSX SCREEN Vibrating Screen Types utilizes advanced vibratory technology to effectively grade and classify a wide range of materials, including sand, coal and aggregate. Built with durability and reliability in mind, it features customizable screen configurations and adjustable vibratory settings to meet your specific processing needs.

Linear vibrating screen can be used to realize automatic operation in assembly line. It has the characteristics of low energy consumption, high efficiency, simple structure, easy maintenance, fully enclosed structure, no dust spillage, etc. It can screen out 7 kinds of materials with different particle sizes. It is suitable for screening sand and gravel in quarries, and can also be used for product classification and dehydration in coal preparation, mineral processing, building materials, electricity and other industries.

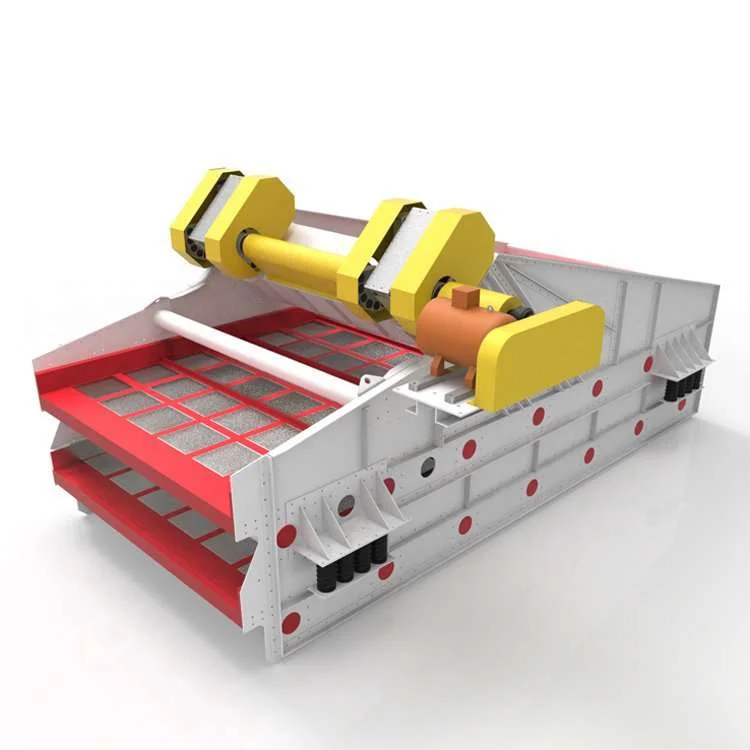

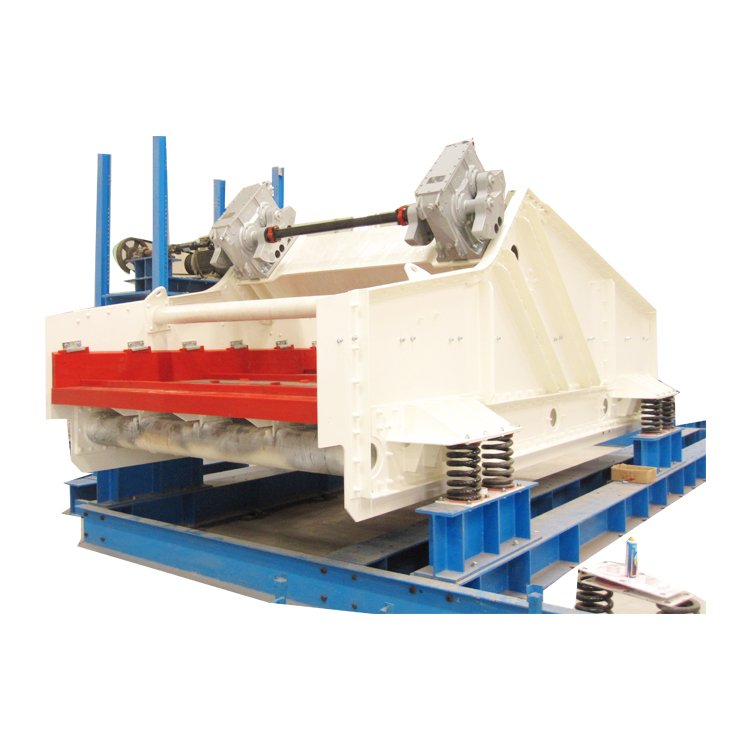

High-frequency screen applies the linear screening principle and linear vibration theory. The exciting force is directly supplied by two vibration motors installed on the exciting beam, which can reliably and smoothly transmit the power and linear vibration force, so that the screen body can directionally vibrate the material at a predetermined frequency and dehydrate it through the screen surface.

Wet Vibrating Screen is primarily used for separation and dewatering of materials in wet processing applications. It can effectively handle slurries and wet materials, ensuring accurate size and minimal clogging.

.jpg)